16 Mar Duct Cleaning for North Sea Oil Rig

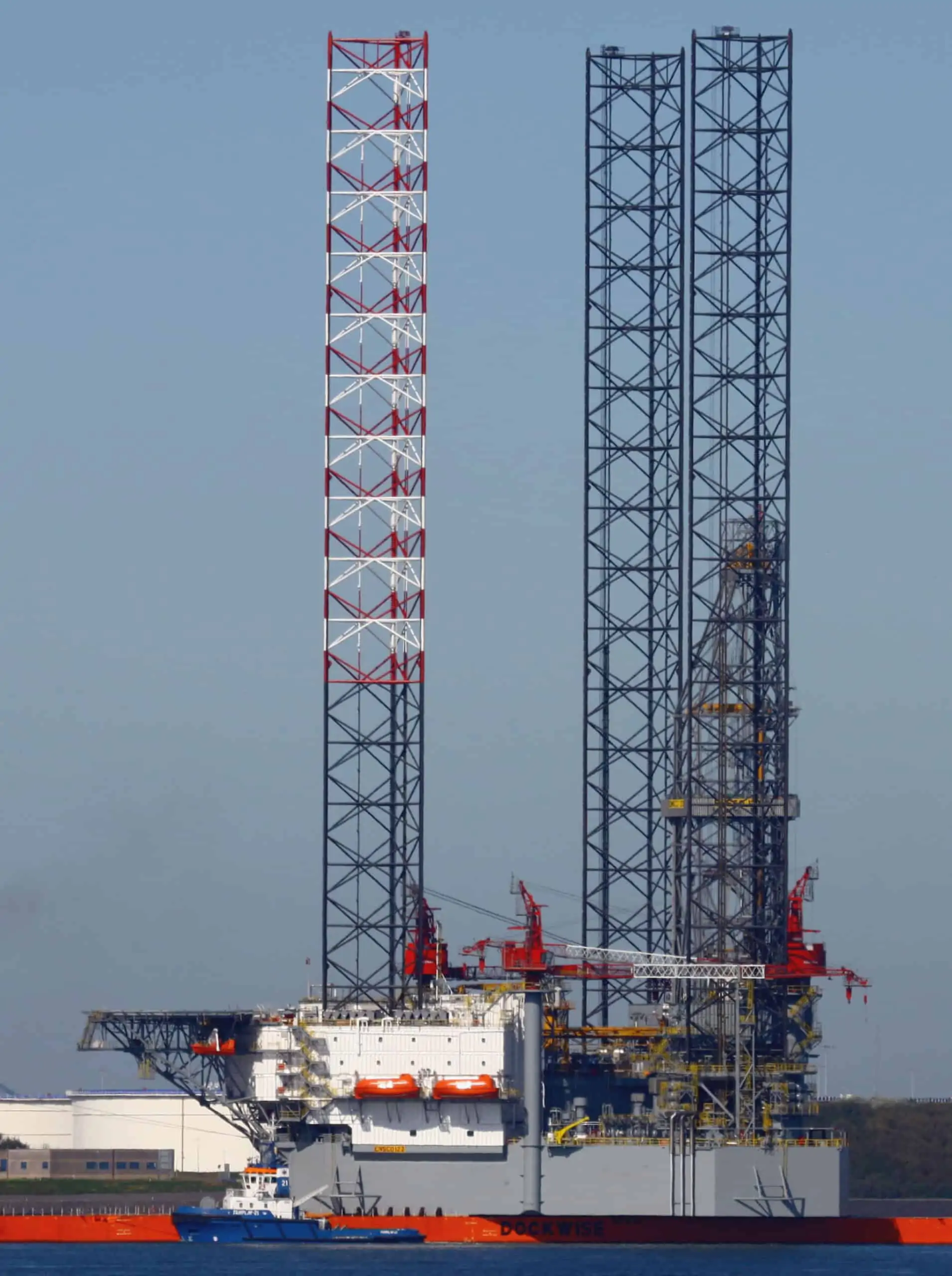

Introduction to the Project: Duct Cleaning for North Sea Oil Rig

The Deduct team have been undergoing survival training in preparation to carry out duct cleaning works on a North Sea oil rig.

In the demanding and often unpredictable environment of the North Sea, maintaining the highest standards of operational safety and efficiency is not just a goal, but a necessity. At the heart of this commitment lies the essential yet frequently overlooked task of duct cleaning. The Deduct team, known for our meticulous attention to detail and unwavering dedication to safety, is embarking on a challenging yet vital project: Duct Cleaning for a North Sea Oil Rig.

This project is more than just routine maintenance; it’s a testament to our team’s ability to adapt, innovate, and excel in one of the most challenging industrial environments in the world. The North Sea, known for its harsh weather conditions and demanding operational requirements, presents unique challenges that only the most skilled and well-prepared teams can tackle. Our mission is to ensure that the air quality and ventilation systems on the rig are maintained to the highest standards, contributing not only to the efficiency of operations but, more importantly, to the health and safety of all personnel on board.

In this blog post, we will delve into the intricate process of preparing for such a demanding task, from the rigorous BOSIET training our team has undergone to the specialised equipment and techniques we employ. Join us as we explore the depths of our preparation, experience, and commitment to excellence in the face of the formidable North Sea.

BOSIET Training: Preparing for Offshore Challenges

A cornerstone of our preparation for the North Sea oil rig project is the comprehensive ‘Basic Offshore Safety Induction and Emergency Training‘ (BOSIET). This training is not just a regulatory requirement; it’s a fundamental part of our commitment to safety and excellence in offshore operations.

The BOSIET programme equips our team with crucial survival skills, emergency response techniques, and a deep understanding of safety practices essential for working in the offshore oil and gas industry. Key components of the training include:

Helicopter Safety and Escape: Learning how to evacuate from a helicopter submerged in water, a scenario that, while unlikely, is critical to prepare for in offshore operations.

Firefighting and Self-Rescue: Training in effective firefighting techniques and self-rescue in various scenarios, ensuring readiness for any emergency.

Sea Survival Skills: Preparing our team for survival at sea, including first aid and lifeboat drills, is essential for the unpredictable North Sea environment.

By undergoing BOSIET training, our team is not only accredited to work on offshore rigs but also equipped with the knowledge and skills to handle the unique challenges posed by the North Sea. This training underscores our proactive approach to safety and our dedication to maintaining the highest standards in every aspect of our work.

Upon completion of the training course, our team will be accredited to work on offshore rigs for the next four years.

Specialist Training for Offshore Safety

BOSIET training will introduce our workforce to safety and emergency practices that could be required while working in a specialist offshore working environment. The course includes being submerged in water within a simulated helicopter. We’ll be trained on how to remove a window and escape quickly & safely. The accreditation has been designed to equip teams with the necessary basic knowledge for working in the offshore oil and gas industry.

Previous Experience and Current Project Scope

We have previously worked on the same rig while it was stationed inland. On this occasion, the rig is situated in the North Sea, roughly 150 miles from Aberdeen. The duct cleaning works comprise fresh air supply & general extract ductwork within the accommodation areas, working areas and galley (onboard kitchen).

Duct Cleaning Process and Equipment

The duct cleaning process on an offshore oil rig is a complex and meticulous operation, requiring specialised equipment and techniques. At Deduct, we employ a combination of advanced technology and proven methods to ensure thorough cleaning and maintenance of the rig’s ventilation systems. Here’s an insight into our process and the equipment we use:

Rotary Brushing Machines: These are the backbone of our duct cleaning process. The rotary brushing machines are designed to navigate through the ductwork, dislodging any accumulated debris and dust. Their flexibility and power make them ideal for the intricate and varied duct systems found on oil rigs.

Air Movers: Working in conjunction with the rotary brushes, air movers are used to enhance the cleaning process. They help in dislodging and removing debris by creating a powerful airflow through the ducts, ensuring that even the most stubborn particles are removed.

Degreasing of Kitchen Extraction Systems: The kitchen extraction systems, crucial for maintaining a safe and hygienic environment in the galley, receive special attention. We use eco-friendly degreasing agents and detailed cleaning techniques to ensure these systems are free from grease and other contaminants, reducing the risk of fire and improving overall air quality.

Safety and Precision: Safety is paramount in every aspect of our operation. Our equipment is regularly inspected and maintained to the highest standards, and our team is trained to operate it with precision and care, ensuring not only the effectiveness of the cleaning process but also the safety of all personnel involved.

Customised Solutions: Recognising that each oil rig has its unique challenges, we tailor our approach to meet the specific needs of each project. This customisation allows us to be efficient and effective, ensuring that our duct cleaning services meet the rigorous demands of the offshore environment.

Through this combination of advanced equipment and skilled techniques, we ensure that the ductwork on the oil rig is cleaned to the highest standards, contributing to the safety, efficiency, and longevity of the rig’s operations.

Commitment to Health and Safety Standards

This work is part of the rig’s yearly maintenance programme to ensure it meets health and safety standards.

Looking Forward to New Challenges

We’re always excited to tackle new challenges, and we’re looking forward to completing the medical and fitness course required to work in this demanding environment.

If you’re interested in learning more about this project or any of our ductwork cleaning services, please get in touch.